7 Signs It's Time to Replace Your Concrete Floor with Epoxy: Complete Guide to Upgrading Your Flooring

Concrete floors endure tremendous daily stress from vehicle traffic, chemical exposure and harsh weather conditions. Over time, even the most durable concrete surfaces develop cracks, stains and structural damage that compromises both safety and appearance.

When we notice persistent cracking, oil stains or surface deterioration, these are clear indicators that our concrete floor needs replacement with a high-performance

epoxy coating system. Epoxy flooring offers superior chemical resistance, impact durability and moisture protection that bare concrete cannot match.

We will examine seven specific warning signs that signal when concrete floor replacement becomes necessary. Understanding these indicators helps us make informed decisions about upgrading to epoxy flooring before minor issues become costly structural problems.

Understanding Why Epoxy Flooring Outperforms Concrete

Epoxy flooring outclasses bare concrete in every way—durability, aesthetics and resistance. Combining advanced resin technology with superior adhesion, epoxy coatings create a protective layer that eliminates maintenance headaches while elevating design appeal.

Cracks and Chips: Structural Red Flags You Can’t Ignore

Small cracks may seem harmless, but they act as gateways for moisture and corrosion. Over time, these imperfections compromise structural integrity and cause safety issues.

Key causes include:

- Foundation shifting or impact damage

- Freeze-thaw cycles

- Heavy machinery or vehicle traffic

Epoxy flooring fixes this by:

- Filling and sealing surface cracks permanently

- Preventing moisture penetration

- Reinforcing the substrate with industrial-grade resin

Once applied, epoxy creates a flawless, impermeable surface that stops deterioration in its tracks.

Persistent Stains and Peeling Paint

When oil stains, tire marks, or chemical discoloration dominate your concrete, aesthetics—and hygiene—take a hit. Peeling paint shows that the coating has failed, usually because of trapped moisture or insufficient surface preparation.

Common causes:

- Road salt and oil contamination

- Harsh cleaning chemicals

- Poor ventilation or humidity buildup

Epoxy’s advantage:

- Conceals existing stains beneath a seamless coat

- Prevents future discoloration

- Offers a reflective, high-gloss finish that brightens any space

Your once-stained floor transforms into a professional-grade surface that looks clean and stays clean.

Dusting and Efflorescence: The White Powder Problem

If you constantly sweep up fine white dust, your concrete is deteriorating. Efflorescence occurs when moisture draws salts to the surface, leaving behind powdery residue.

Why it happens:

- Lack of sealant or vapor barrier

- Moisture migration from beneath the slab

- Temperature fluctuations

Epoxy eliminates the issue by:

- Creating an airtight, moisture-resistant barrier

- Locking out contaminants and salts

- Maintaining a polished, dust-free surface year-round

Epoxy flooring keeps your space cleaner, healthier and far easier to maintain.

When Maintenance, Safety and Appearance Demand an Upgrade

If you’re pouring more effort into cleaning than using your space or if your floors feel unsafe and unattractive, epoxy flooring offers a sustainable fix.

High Maintenance Costs and Constant Cleaning

Bare concrete absorbs dirt and liquids like a sponge, demanding frequent resealing and washing. Over time, those maintenance costs add up.

Why it’s costly:

- Frequent resealing cycles

- Labor-intensive upkeep

- Grime and oil absorption

Epoxy cuts expenses by:

- Providing a non-porous, easy-to-clean surface

- Eliminating waxing or polishing

- Extending lifespan up to 20 years

An epoxy upgrade pays for itself with minimal upkeep and long-term value.

Salt and Chemical Damage in Industrial or Garage Spaces

Garage and industrial environments expose concrete to road salts, oil and harsh chemicals—all of which accelerate erosion.

Typical signs:

- Pitting and surface scaling

- Flaking or spalling concrete

- Corrosion around joints and drains

Epoxy protection includes:

- Chemical and salt resistance

- Seamless application for heavy-duty use

- Enhanced safety with slip-resistant textures

Epoxy forms a chemical-resistant armor—ideal for factories, auto shops and warehouses.

Slippery or Uneven Floors: A Hidden Safety Threat

Uneven or slick floors endanger workers, visitors and property. Whether from moisture buildup or surface wear, unsafe flooring invites costly accidents.

What causes unevenness:

- Erosion or settling substrate

- Spilled chemicals or oil

- Poor-quality coatings

Epoxy solves this by:

- Offering slip-resistant additives like quartz sand or flakes

- Creating a level, stable walking surface

- Enhancing traction even in wet environments

With epoxy flooring, safety becomes built-in—not optional.

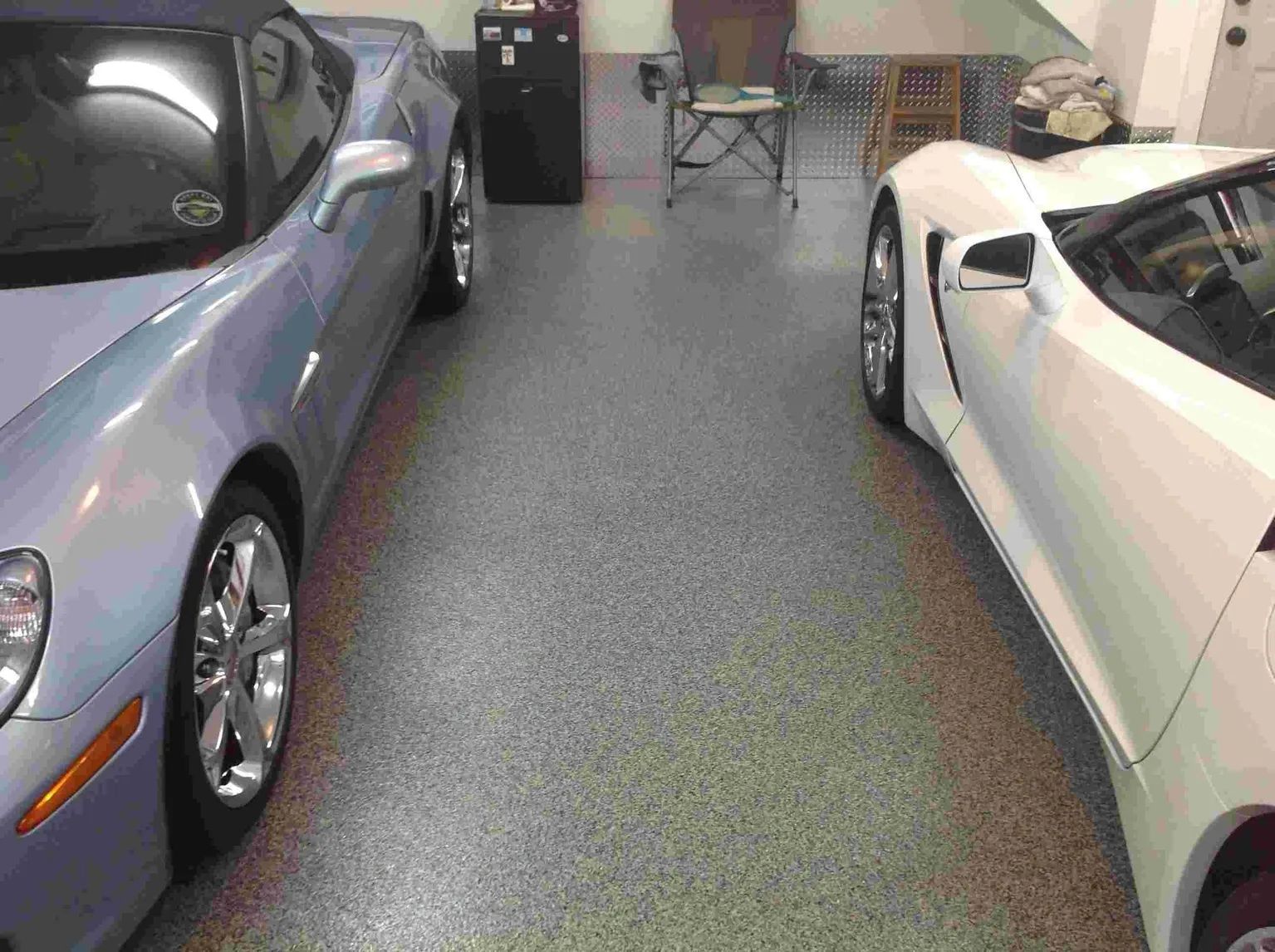

A Dull, Worn-Out Look That Devalues Your Space

Concrete naturally loses luster with age. Dull, stained floors reflect neglect—not professionalism or pride of ownership.

Why it fades:

- UV exposure and abrasion

- Staining and surface wear

- Lack of sealing protection

Epoxy restoration benefits:

- High-gloss, mirror-like finish

- Customizable designs—metallic, flake or quartz

- Immediate property value boost

Whether residential or commercial, epoxy flooring rejuvenates your environment with vibrant color, durability and luxury appeal.

Frequently Asked Questions

Epoxy flooring decisions involve understanding durability expectations, installation requirements, safety considerations and financial investments. Cost factors, application limitations and property value impacts are common concerns for both residential and commercial projects.

What factors determine the lifespan of an epoxy flooring system?

The quality of surface preparation is important for how long epoxy lasts. To ensure strong adhesion, you should properly grind the concrete, clean the surface thoroughly and test for moisture.

Traffic levels and load requirements influence wear patterns. Industrial spaces with heavy machinery experience different stress than residential garages.

Environmental conditions like temperature fluctuations and chemical exposure impact coating performance. UV-stable formulations resist yellowing in areas with natural light exposure.

Installation quality determines long-term success. Professional application ensures proper thickness, curing conditions and seamless coverage.

Can epoxy coatings be applied to concrete with pre-existing damage?

Minor surface cracks and small chips can be repaired before epoxy application. We fill hairline fractures with specialized crack injection compounds.

Extensive structural damage requires concrete replacement before coating. Deep cracks, spalling, or unstable surfaces compromise adhesion performance.

Active moisture issues must be resolved first. Hydrostatic pressure and ongoing water infiltration prevent proper epoxy bonding.

Surface contamination from oils or chemicals needs removal. Proper degreasing and etching restore concrete porosity for mechanical adhesion.

Are epoxy floors safe and non-slippery under wet conditions?

Standard epoxy creates smooth surfaces that become slippery when wet. We recommend anti-slip additives for areas prone to moisture exposure.

Broadcast aggregate systems provide excellent traction. Quartz sand, aluminum oxide or rubber granules increase surface texture significantly.

Textured roller applications create subtle grip patterns. These maintain aesthetics while improving safety in moderate-risk environments.

Effective drainage design prevents water buildup using sloped installations and perimeter drains to eliminate standing water.

What is the typical cost range for residential epoxy floor installation per square foot?

Basic epoxy systems cost between $3 and $8 per square foot for installation. Single-coat applications that require little surface preparation are usually cheaper.

Decorative systems cost $8 to $15 per square foot. Metallic finishes, color flakes and multi-coat applications increase material and labor requirements.

Surface condition affects pricing significantly. Extensive grinding, crack repair, or oil stain removal add preparation costs.

Geographic location influences labor rates. Urban markets typically command higher installation prices than rural areas.

How do epoxy floor resurfacing and complete replacement differ in terms of benefits?

Resurfacing applies new coatings over existing epoxy systems. This option works when adhesion remains strong and substrate damage is minimal.

Complete replacement removes old coatings and addresses underlying concrete issues. We recommend this approach for failed systems or structural problems.

Cost differences are substantial between approaches. Resurfacing typically costs 40-60% less than complete replacement projects.

Performance expectations vary significantly. New installations provide longer service life and better warranty coverage than overlay systems.

Does installing epoxy flooring add value to a residential or commercial property?

Installing quality epoxy can slightly increase the value of residential properties. Garage improvements typically recover 50-70% of their costs. For commercial properties, epoxy helps lower maintenance costs and attracts tenants. In industrial facilities, it improves efficiency and ensures safety compliance.

Market perception varies by property type and local preferences. High-end decorative systems appeal more to luxury home buyers.

Durability improvements provide long-term value beyond initial installation costs. Reduced floor maintenance and replacement cycles benefit property owners financially.

Upgrade Your Floor—Transform Your Space with Epoxy

When your concrete floor shows wear, don’t wait for more damage. Epoxy flooring turns cracked surfaces into durable, polished and safe areas—a smart investment in performance and longevity.

Get a professional inspection and a personalized quote for epoxy flooring—schedule your free epoxy flooring consultation today.